Resilience

Improve quality through visibility to all stages of manufacturing.

Rank Your Vendor Base

Improve On-Order Inventory Management

Verify with Geo Tracking

Quality inspections validated by geo tracking

Visibility at every stage of manufacturing with simplified booking for all types of inspections including:

- 3rd party inspections

- Self-inspections

- Shadow inspections

With location tracking to monitor progress and detect discrepancies.

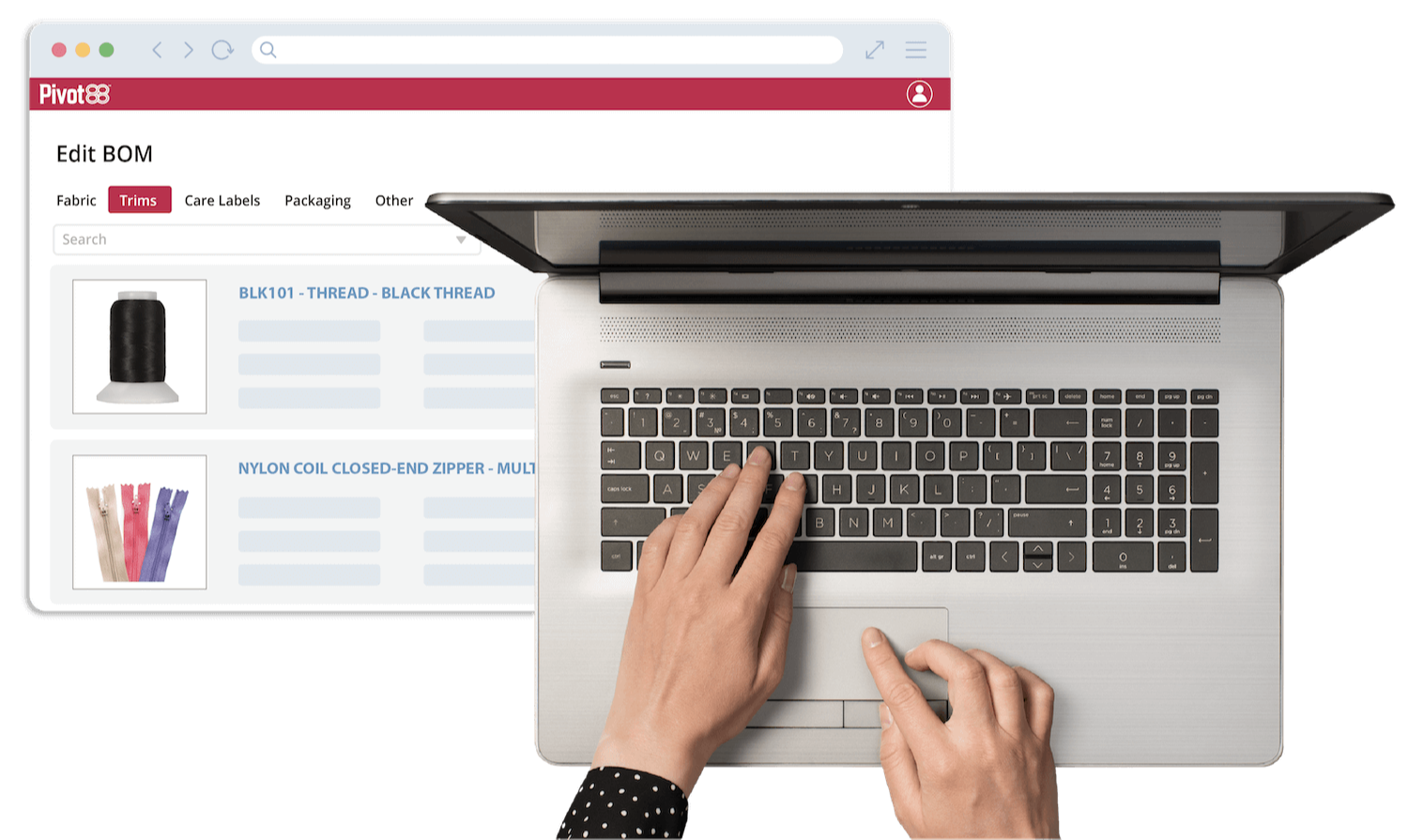

Simplified material management

Manage SKUs, BOMs, and Raw Materials with ease, allowing you to collaborate with suppliers, organize and visualize materials, and create structured BOM documents in a breeze.

Seamless integration

We understand that every business operates differently with unique systems and workflows in place. Our bi-directional integration capabilities connects to your existing systems to synchronize information across various platforms and departments simplifying your processes and boosting efficiency.

Unleash the power of AI

Digital means data...and in many cases too much data. Our artificial intelligence helps you make sense of this data tsunami, altering you to risks to help you mitigate, navigate, and overcome obstacles before they become costly mistakes.

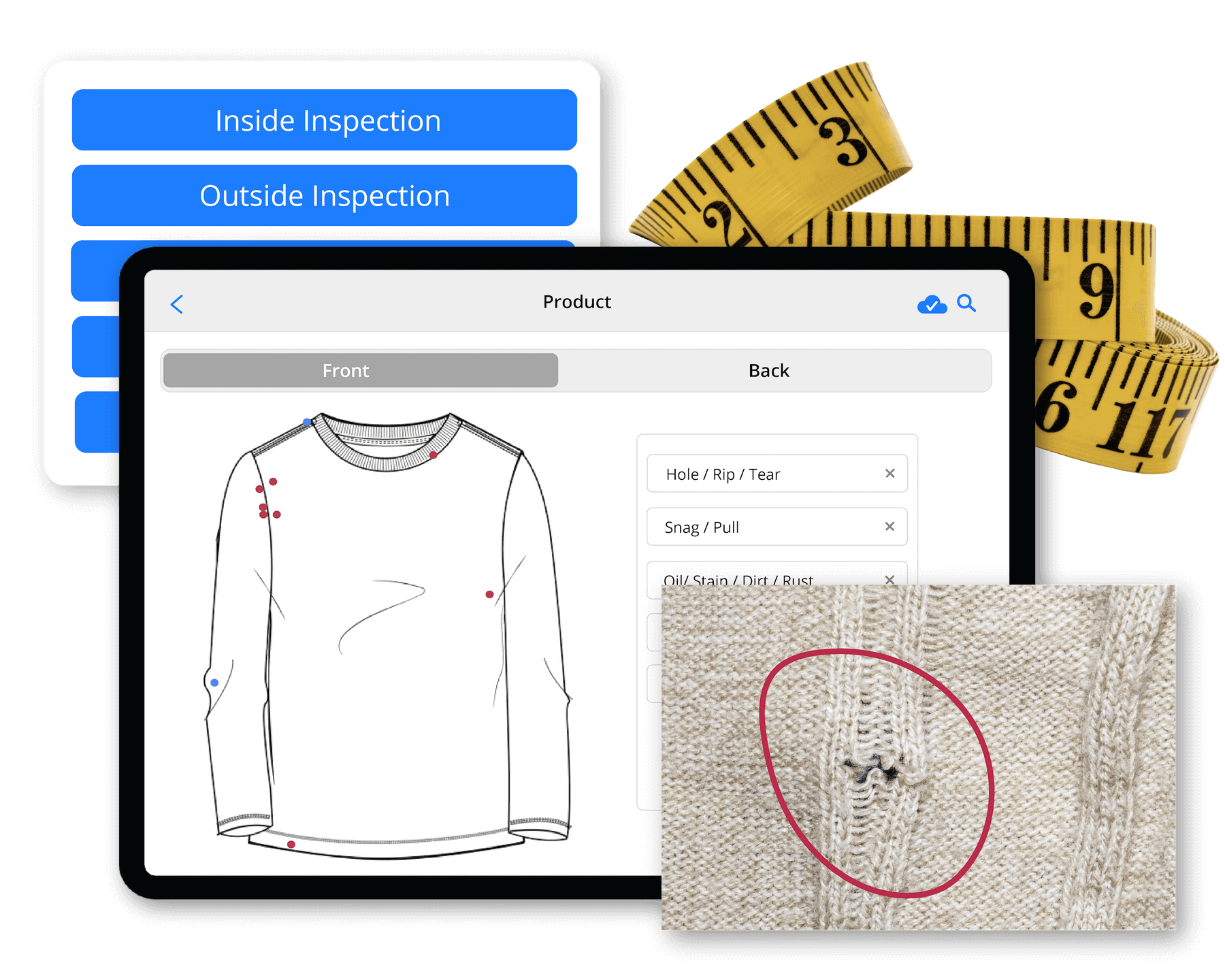

Instant capture

Our mobile app offers many photo and comment capabilities. Whether used online or offline, users can capture defect data in their native language directly on the factory floor.

Configurations can be made by process with the option to visually identify defect locations on a product sketch.

Easily connect to external devices, such as a smart tape, to work more efficiently, capturing measurements quickly and more accurately.

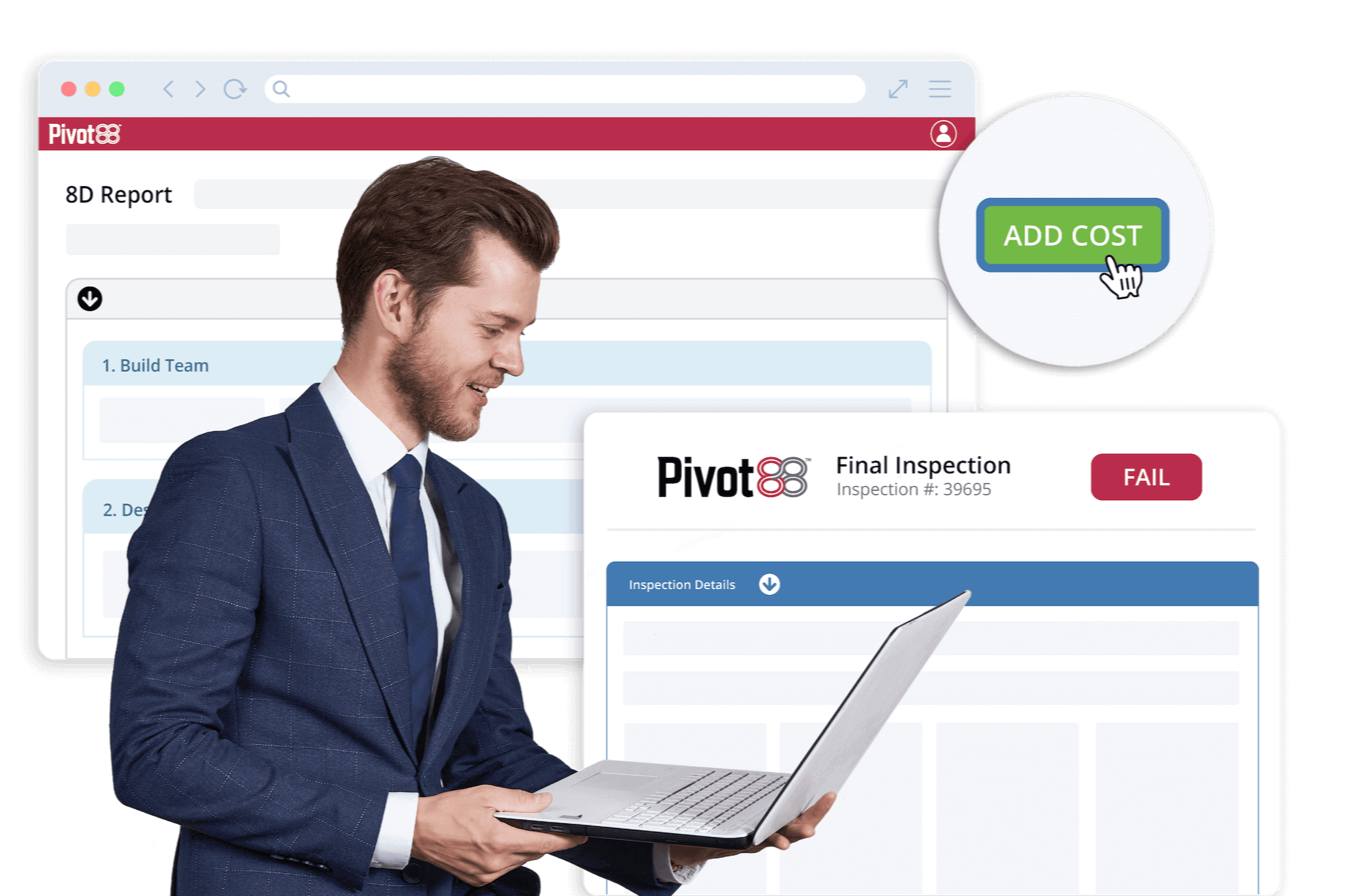

Track the cost of quality

Track non-conformities and request 8D reports to suppliers to implement immediate and future corrective action plans. Costs can be easily tracked and charged back to the supplier. Validate that corrective action plans are in place and successful by requesting follow-up audits.